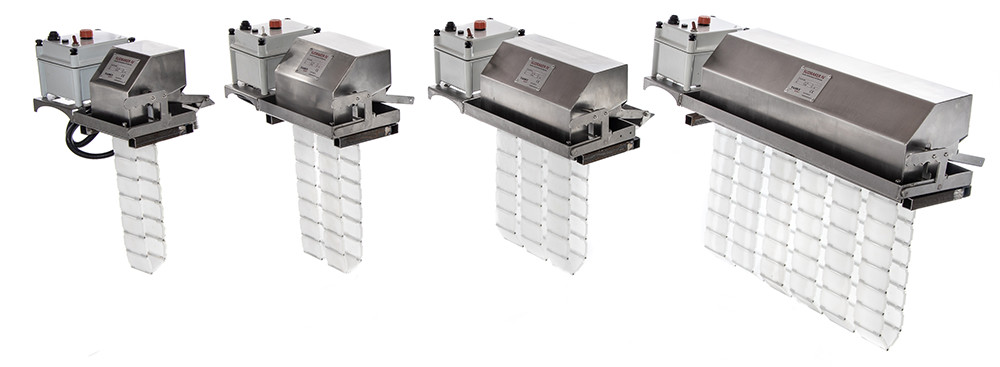

Sudraker™ Oil Skimmers

Hostile environment oil removal

At Tanky Systems, we specialize in efficiently removing surface oil from process tanks, machine sumps, ground sumps, and storage vessels using advanced oil skimmers.

Key elements of our oil skimmers

- Low maintenance ‘and easy cleaning’

- Simple to install ‘with multiple mounting options’

- Up to 5 litres of oil removal per hour per belt

- Excellent oil/water separation

- Four sizes available – 1,2,3 &6 belt versions

- Purpose made quality accessories

Efficient oil removal

Specializing in surface oil removal from tanks, sumps, and storage vessels with precision.

Where are oil skimmers used?

Separating oil from water is an extremely common requirement across many industries, and there are many different ways of achieving this, from using cyclones and centrifuges, to specific gravity weirs or osmosis.

What sort of oil skimmer to choose?

The three main types of oil skimmer are belt skimmer, rope skimmer and disk skimmer and each type of skimmer has its place in the market. Rope skimmers and belt skimmers are well suited to installations where fluid levels are liable to fluctuate.

Why choose Tanky oil skimmers?

Tanky’s Sudraker™ oil skimmers have been designed specifically to work reliably in more hostile environments, and are fitted with our unique fatigue-free tank track skimming belt, which boasts an impressive 5 year warranty. They have been designed and tested on industrial de-greasing equipment.

Customer Testimonials

We needed help to manage our oil containment in our on-site drainage channels. After an initial consultation with Garry, we decided to trial one of their twin belted oil skimmers on one of our worst affected drainage channels

Since 2010 we have been using Sudraker II oil skimmers in waste water catchment sumps on our Power Station site. These sumps can sometimes be contaminated with fuel oils and lubricants and so the Sudraker skimmers were installed to remove these oils to reduce the demand on downstream wastewater treatment systems.

We bought the first Sudraker II oil skimmer shortly after they had been released into the market place back in August 2001, the first unit we bought was fitted to a coolant recycling plant having had problems with several other makes of oil skimmer.